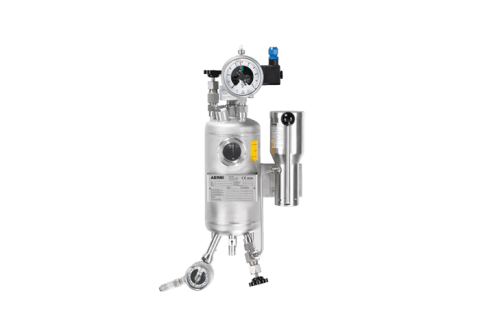

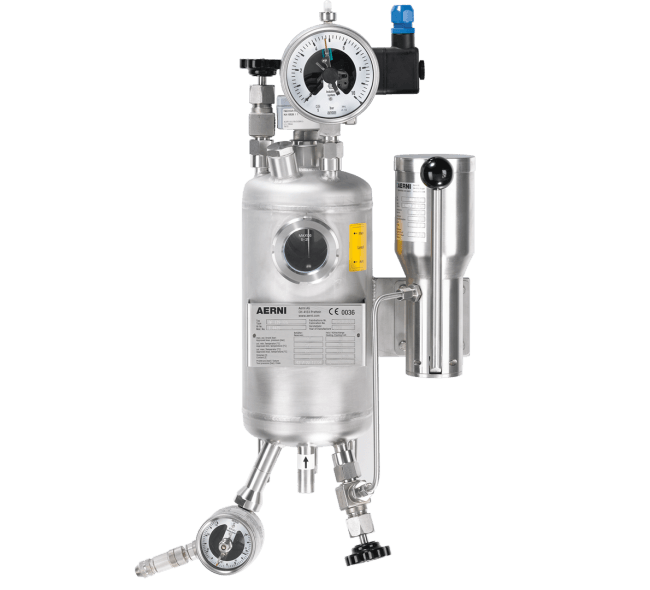

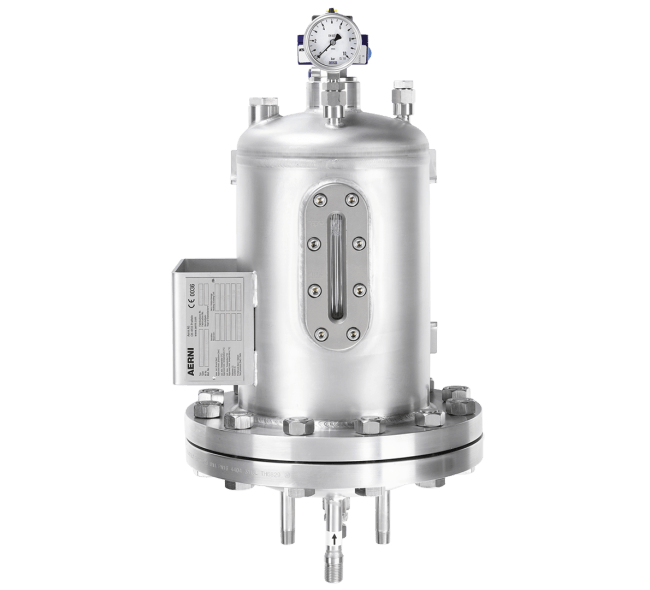

Standard version in stainless steel

Chemical vessels

Standard version in stainless steel

For 3 and 6 litres with round hole sight glass or with oblong hole sight glass for 6 and 12 litres. All stainless steel design. Vessels and fittings are free of non-ferrous metal, aluminium, steel or zinc, except for special fittings on customer request.

to assist you

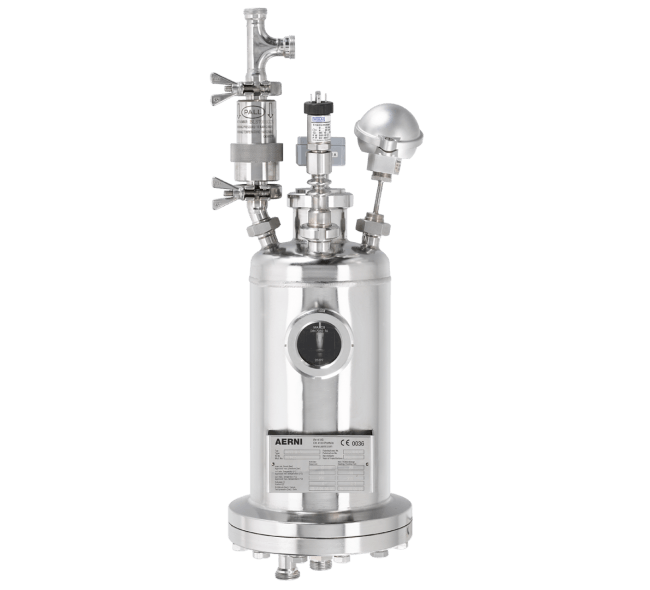

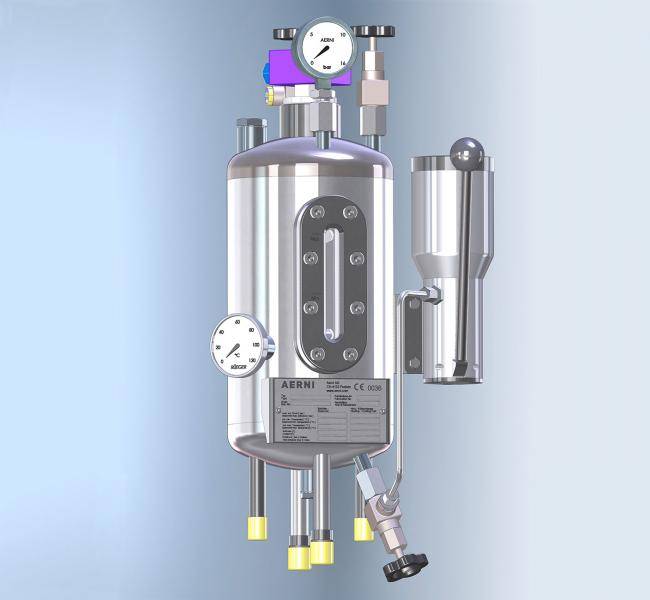

For aseptic production processes with no dead spaces in stainless steel

Sterile vessels

For aseptic production processes with no dead spaces in stainless steel

There are no dead spaces where germs can accumulate. Interior with spigots and weld seams ground to Ra 0.6 µm, electropolished inside and out. Two-part vessel with round sight glasses in sterile design and sterile screw connections for fittings. All stainless steel design.

to assist you

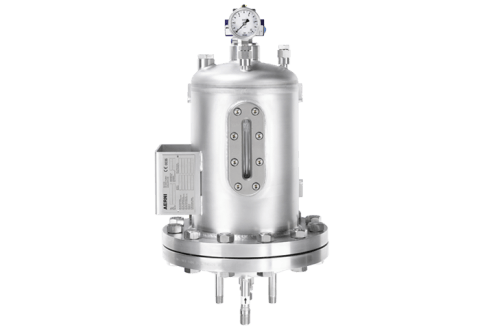

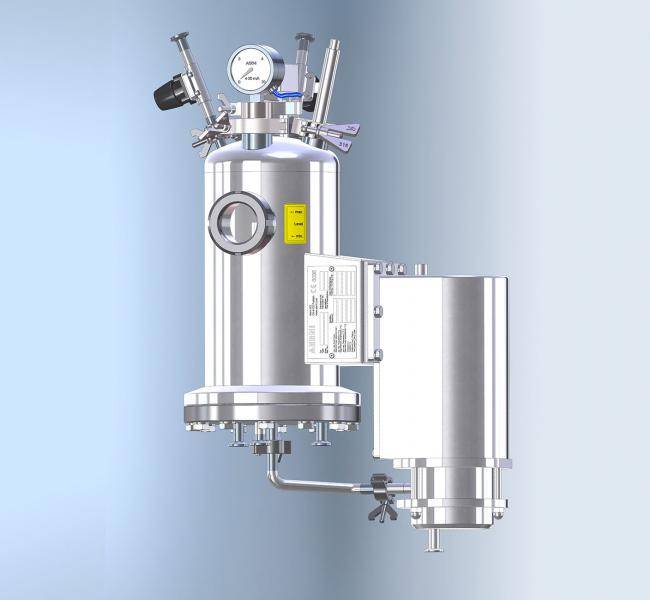

Construction, design and instrumentation according to customer specifications

Customised vessels

Construction, design and instrumentation according to customer specifications

The AX 219 ZS was developed for applications that require a high degree of automation – a 12-litre vessel that can be equipped with a wide range of measuring and control devices. For a more detailed specification of your barrier pressure vessel, please print out the corresponding PDF, fill it in and fax it to +41 61 811 12 11 or send it by email to info@aerni.com.

Aerni barrier pressure vessels

Aerni sterile barrier pressure vessels

Construction, design and instrumentation according to customer specifications

Sealing systems

Construction, design and instrumentation according to customer specifications

For lubricating and cooling chemical apparatus. A pressure reducer and float valve regulate the fluid level in the reservoir. Self-priming pumps. Measuring devices for plant monitoring. ATEX-compliant components. Sturdy stainless steel structure.

In-house development by Aerni

Manual refill pump

In-house development by Aerni

Made of 1.4404 stainless steel for various applications:

– Refilling of barrier fluid in barrier pressure units during operation

– Lubricating of plunger bearings and glands

– Adding of chemicals in pressure reactors

Aerni barrier pressure vessels are used in the chemical, pharmaceutical, cosmetics and food industries to store, maintain pressure and cool barrier media in a sealing loop. The vessel and, if available, the fittings are made entirely of stainless steel. Aerni guarantees the quality of the manufactured products and carries out the necessary approval tests. Aerni also offers the construction of prototypes in order to extensively test and optimise the function in the real process.

functional principles

Two different types of systems, thermosiphon and forced circulation systems, are used to circulate the barrier fluid. The mechanical seal performs a different role depending on the system.

THERMOSIPHON

Gravity circulation

In the case of the thermosiphon or gravity circulation, the circulation functions on the principle of the temperature differences in the inlet and outlet of the barrier pressure vessel. The cold sealing medium flows into the mechanical seal. Once there, the medium heats up and flows back into the barrier pressure vessel via the return pipe, where it cools down again at the heat exchanger and flows back into the mechanical seal. Thermosiphon systems work with pressurised gas overlay to ensure a defined differential pressure across the mechanical seal.

principle

PDF Scheme

circulation

Gear pump and air filter

With forced circulation, the sealing medium is circulated via a gear pump. If the sealing pressure vessel is operated without pressure, an air filter must be fitted at the compressed gas connection so that no vacuum can develop in the vessel. In addition, a diaphragm or a pressure relief valve must be installed in the return line to maintain a defined differential pressure above the mechanical seal.

Differential pressure in case of power failure

In the event of a power failure (no forced circulation), there would no longer be any differential pressure, so a pressurised gas overlay is recommended in any case. The differential pressure across the mechanical seal can thus be maintained for a longer period of time in the event of a power failure, provided that the mechanical seal does not have a leak.

operating principle

PDF Scheme

Aerni barrier pressure vessels are used in the chemical, pharmaceutical, biotechnology, food and cosmetics industries for storing, pressurising and cooling barrier media in sealing loops with mechanical seals.

Aerni barrier systems

Quench and seal vessels

Dripping fluid vessels

Thermosiphon systems

Thermosiphon chemical vessels

Forced circulation systems

Pharmaceutical vessels

Hastelloy vessels

Manual refill pump

Accessories and spare parts

to advise you

daniel.mueller@aerni.com